Human Organs-on-Chips wins Design of the Year 2015

The winner and all of the nominated projects, are currently on display at the Design Museum until March 31, 2016

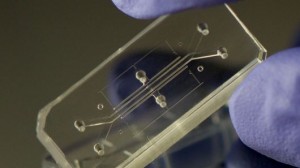

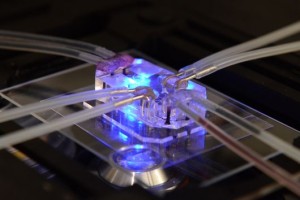

A micro-device lined with living human cells able to mimic the function of living organs has been declared the overall winner of the Design Museum’s Design of the Year Award for 2015.

Something of a departure from last year’s winner, the Heydar Aliyev Center, by Zaha Hadid, Human Organs-on-Chips is the competition’s first winner from the field of medicine in its eight-year history. Designed by Donald Ingber and Dan Dongeun Huh at Harvard University’s Wyss Institute, the Human Organs-on-Chips project comprises a series of chips that mimic real human organs, including a lung-on-a-chip, and gut-on-a-chip.

As we previously reported, the research could prove beneficial in evaluating the safety and efficacy of potential medical treatments, in addition to lessening demands on animal testing, accelerating drug discovery, and decreasing development and treatment costs.

“One of the most important things about the Designs of the Year award is the chance that it gives the museum to explore new territory,” says London’s Design Museum Director, Deyan Sudjic. “The team of scientists that produced this remarkable object don’t come from a conventional design background. But what they have done is clearly a brilliant piece of design.”

The winner and all of the nominated projects , are currently on display at the Design Museum until March 31, 2016.\

References:http://www.gizmag.com/